-

- Capillary

- Dispensing nozzles

- Vacuum Chuck

- Electronic Cigarette

- ESD Safe Nozzle Tip

- Die Bonding Collets

- EFO Wand

- Piston

- ESD Safe Tweezers

- Cosmetics Package Parts

- Ceramic Bearing

- Ceramic circuit board

- Ceramic Substrate

- Ceramic Heater

- Ceramic package

- Micro-EDM

- Ceramic brazed component

- Spring Nozzle

- Ceramic coffee burrs

Advanced Ceramic Material Expert

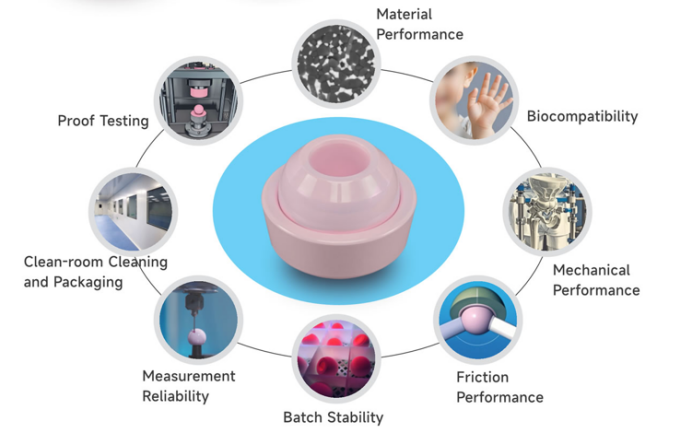

New Products-Ceramic Hip Joint Ball & Liner

Material Performance

Hip ioint balls and liners use ZTA(Zirconia Toughened Alumina)ceramic material, which has been used for decades. lt has excellentbiocompatibility, high chemical stability, and high wear resistance.

Proof Testing

After 100% proof testing,it can ensure that it can withstandcorresponding forces in the human physiological environment,reducing the risk of fracture, thus ensuring its safety.

Clean-room Cleaningand Packaging

The cleaning process is carried out in a clean-room environmentto reduce pollution, prevent microbial growth, maintain a stabletemperature and humidity environment, which is beneficial tothe physical and chemical stability of the product.

Measurement Reliability

Adopt high-precision(0.7um)coordinate measuring machinesto measure the dimensions, and use high-precision(0.001um)roughness testers to ensure the consistency ofsurfaceroughness,thus guaranteeing the accuracy ofproductdimensions and surface quality.

Biocompatibility

The ceramic material has excellent chemical stability. It does notreact with various body fluids in the human body (such as blood.tissue fluid, etc.),reducing the risk of Inflammatory response.

Mechanical Performance

Alumina itself has a high hardness, and ZTA material has an evenhigher hardness, which improves the material's wear resistanceand makes it more reliable in the human body environment.

Friction Performance

Its friction coefficient is still very low in the body fluidenvironment, and its good hardness characteristics ensure thatthe material will not easily wear under friction stress, thus givingit excellent wear resistance.

Batch Stability

18 years ofexperience in ceramic material research anddevelopment, imported equipment ensures hiah-precisionmachining size,fine machining quality and stable machiningperformance.Automated production control is completed in aconsistent environment to ensure the stability of product quality.

Knowledge Base

Product

Suntech Advanced Ceramics (Shenzhen) Co.,Ltd

Application

Contact Us

Suntech Applied Materials (Hefei) Co.,Ltd

TEL:86-755-26584521

EML:info@esuntech.com

ADD:303B, Block A1, Fuyong Zhihuiyuan, Fuyong Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

TEL:86-0551-88788886

EML:info@esuntech.com

ADD:No.11 Huashan Road,Anhui Chaohu Economic Development Zone,Hefei, Anhui,China