-

- Capillary

- Dispensing nozzles

- Vacuum Chuck

- Electronic Cigarette

- ESD Safe Nozzle Tip

- Die Bonding Collets

- EFO Wand

- Piston

- ESD Safe Tweezers

- Cosmetics Package Parts

- Shaft and Sleeve

- Ceramic circuit board

- Ceramic Substrate

- Ceramic plate

- Ceramic package

- Micro-EDM

- Ceramic brazed component

- Spring Nozzle

- Three-Terminal Fuses - Ceramic Heating Elements

Advanced Ceramic Material Expert

Ceramic materials

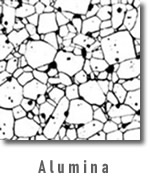

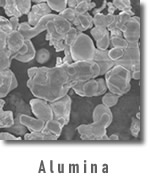

Alumina is a well-known and commonly used precision ceramic material. It has the same sintered crystals as sapphires and rubies. For decades, it has been used in electrical components for its high electrical insulation. It is widely used in mechanical parts due to its high strength, high corrosion resistance and high wear resistance. Because alumina is a relatively balanced material with various mechanical properties, alumina is used in a wide range of applications, including wear resistant products for high temperature industrial furnaces and various electronic components. Due to chemical and physical properties, alumina is stable. It is a well-known precision ceramic material. Thermal properties: heat resistance and thermal conductivity. Mechanical properties: high strength and hardness. Other characteristics: high electrical insulation, strong corrosion resistance and high biocompatibility.

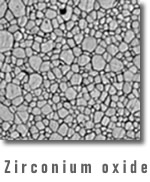

Zirconium oxide is mainly composed of zirconium dioxide. At room temperature, it is a material with high mechanical strength and strong fracture toughness among all major precision ceramics. It can be used to make cutting blades, scissors and knives. Thanks to its excellent surface smoothness, the material can also be applied to pump components. Compared to alumina, zirconia has superior mechanical properties, strength and fracture toughness. It can also be used in milling machines, sliding parts and cutting blades. Zirconium oxide has excellent heat insulation and its thermal conductivity is less than one tenth of the thermal conductivity of other ceramics.

Advanced ceramic materials make today's applications possible, and also lay the foundation for Suntech's products. Due to its unique material properties, advanced ceramics are considered to be one of the most effective materials of our time, with unique mechanical and electrical, Combination of thermal and biochemical properties and performance. These specific features can be further developed, optimized and matched for technical applications. It is also possible to combine different attributes. These materials can be used to design advanced components, perform the required tasks with the utmost precision, and can lead years of competitive materials such as metals or plastics in their respective applications. Components made of ceramic materials are increasingly becoming the only solution that can be used for technical challenges that traditional materials cannot overcome.

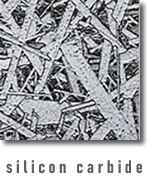

Silicon carbide is mainly composed of SiC and is a ceramic material with excellent corrosion resistance, which can be used in mechanical seals and pump parts. At temperatures up to 1400 ° C, silicon carbide can even maintain its strength. The distinguishing feature of this material is the extremely high electrical conductivity of the thermal and electrical semiconductors. Due to its chemical and physical stability, silicon carbide has high hardness and corrosion resistance.

Silicon nitride is mainly composed of Si3N4, which has excellent thermal shock resistance and excellent high temperature strength. These properties make it an ideal material for automotive and gas turbines. It can be used in turbocharger rotors, hot plugs and hot swaps in diesel engines, and is used in many other different applications. Silicon nitride has high strength and fracture toughness at high temperatures. It is used as a high temperature structural component in automotive engines, gas turbines and combustor components. Silicon nitride has a small thermal expansion coefficient and an extremely high thermal shock resistance.

It is widely used as a high-speed cutting tool, kiln structural material, jet engine parts, cermet materials, and resistance heating elements. It is used to manufacture cutting tools, wear parts, smelting crucibles of metals such as copper, cobalt and bismuth, and wear-resistant semiconductor films. Used as super hard tool material and wear resistant material. It forms a solid solution with many carbides. WC-TiC-Co cemented carbide tools have been widely used. It can also be used as a modified additive for NbC-C and TaC-C ternary system carbides, which can reduce the sintering temperature while maintaining excellent performance and can be used as aerospace materials.

Application

Suntech Advanced Ceramics (Shenzhen) Co.,Ltd

Product

Contact Us

Suntech Applied Materials (Hefei) Co.,Ltd

TEL:86-755-26584521

EML:info@esuntech.com

ADD:303B, Block A1, Fuyong Zhihuiyuan, Fuyong Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

TEL:86-0551-88788886

EML:info@esuntech.com

ADD:No.11 Huashan Road,Anhui Chaohu Economic Development Zone,Hefei, Anhui,China